The oil & gas industry is under pressure to develop cost effective designs without compromising safety. Computational Fluid Dynamics (CFD) software is used for this purpose, but improvements are needed to help solve complex safety and design challenges in oil and gas offshore engineering. DNV GL is launching two CFD joint industry projects (JIP) to meet the industry’s need for more cost efficient and precise decision support. Both JIPs are still welcoming new participants.

CFD software uses numerical analysis and algorithms to assess and solve problems involving fluid flows, providing decision support for addressing, among other, fire and explosion risks. The first JIP will develop guidelines on optimal and cost effective gas detector allocation, and the second JIP will improve explosion safety while avoiding costly overdimensioning of topside structures, through an updated congestion factor database.

Gas detector allocation

Mapping of gas detectors is a balancing act during the design of oil and gas facilities; too few detectors increases major accident risk, while too many increases risk of spurious failures causing production losses, reducing trust and increasing maintenance costs. To complicate matters further, location of detectors are essential for proper coverage and highly dependent on the assumptions and inputs to the allocation analyses, often solved by CFD.

The proposed JIP on Gas Detector Allocation aims to address this challenge by integrating the detailed physical description of consequence modelling by CFD simulations, with process and environmental conditions, incorporating the best practices in international standards.

The JIP will deliver a guideline covering all relevant input parameters that impact the gas detection grid. The main areas of interest, such as the recommended gas cloud size to be detected, gas leak rates to be simulated and influence of confinement/congestion level, will be addressed in the JIP. Guidance on sensitivity assessment of cost impact of production loss and repair will also be included for a complete guideline on recommended gas detector coverage.

“Applying CFD dispersion simulation in determining the optimal number and position of gas detectors is a big step towards an improved detector network. However, the lack of industry guidance on gas detector deployment needs to be addressed to reduce the uncertainties in assessing efficient final gas detector layout,” says Rafael Storch, Senior Consultant, DNV GL – Oil & Gas. “The industry needs more assertive guidelines addressing uncertainties in the results, ultimately reducing the number of sensors and providing optimal gas detector mapping.”

U-CFD JIP

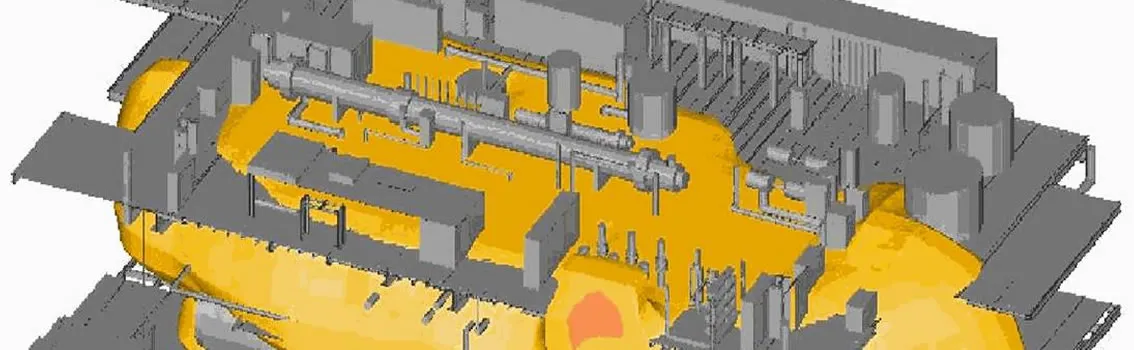

An explosion risk analysis (ERA), developed through CFD software, is very sensitive to the congestion factor and its distribution represented by the geometry model, where the congestion level reflects the final total amounts of pipes, structures and equipments. The U-CFD JIP is inviting participants to share offshore as-built geometries. This will then be available to participants for improved congestion level data; reducing uncertainty and increasing efficiency in early phase engineering and explosion designs.

“The JIP will deliver an improved congestion level database giving a complete documentation of typical physical distribution of pipes, structures and equipment for different areas, equipment packages and skids in as built offshore units,” said Rafael Pereira, consultant, DNV GL – Oil & Gas. “This will not only provide safe and more accurate dimensioning accidental loads for structures and equipment, it will also help avoiding overdimensioning and costly reconstructions, ultimately reducing weight and safely saving costs.”

The improved congestion data will differentiate the congestion level and size distribution for each type of area based on type of process module or utility unit, type of installation such as an FLNG and other floaters or fixed platforms, as well as the congestion levels in typical skids and for specific equipment packages. The project is expected to last one year.

Further information about all of DNV GL's ongoing and proposed Joint Industry Projects