Deployment of carbon capture and storage (CCS) needs to scale much faster

DNV forecasts that the world is on track for CCS to abate less than 4% of fossil CO2 emissions in 2050, compared to the around 20% that would be needed for the world to meet the targets of the Paris Agreement. The majority of senior energy professionals expect CCS to scale significantly in the next five years.

DNV is enabling the commercialization of CCS value chains and delivering assurance to projects and stakeholders: ensuring the safety of CCS operations, maintaining the integrity of CCS infrastructure, and driving cost efficiencies.

- CO2 capture – Selecting the right capture technology is critical to success across the project value-chain. In recent years the focus has moved beyond CO2 capture from gas processing or fossil fuel power generation to include hard-to-abate industries such as cement, steel, refining, hydrogen, and ammonia.

- CO2 pipelines – Connecting CO2 sources and capture locations to permanent geological storage sites is an essential part of the CCS chain. Today, CO2 is primarily transported through pipelines.

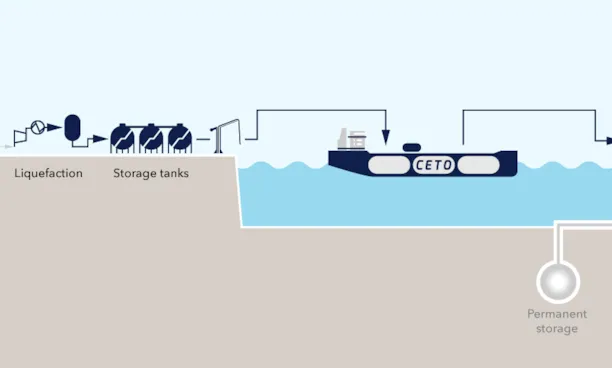

- CO2 shipping – Alongside pipelines, CO2 shipping can enable flexible and scalable CCS infrastructure that can adapt to future capture projects and storage sites. Ships are also preferable for small or short lifetime CO2 sources that cannot justify a dedicated pipeline.

- CO2 storage – For geological storage of CO2, it is fundamental to create confidence that the geological formations selected for CO2 storage are suitable for the purpose, will deliver long-term emission reductions and do not involve unacceptable risk.

- Safety - The application of rigorous hazard management processes combined with an adequate understanding of the properties and behaviours of CO2 in the different parts of the CCS value-chain.

- Onboard carbon capture and storage on ships - Onboard carbon capture is a technology that captures carbon dioxide emissions from ships during operation. It involves capturing CO2 from exhaust gases, separating it, and storing it onboard for eventual offloading.

- Value chains and market development – For CCS technologies to be realized globally, it is the near-term actions that count. From financing to policy and partnerships, industry and government players need to take action today to build the CCS market of the future.

DNV provides world-class CCS expertise for technical assurance, testing, advisory and risk management

With more than 20 years of CCS experience, DNV expertise can make your objectives to decarbonize a reality. Insight into feasibility is critical, and so is the trust and assurance you need to bring your asset to life and sustain important stakeholders on your decarbonization journey.

Our trusted expertise spans the entire global CO2 value chain:

- Technology qualification

- Techno-economic due diligence and benchmarking

- Feasibility and risk assessments

- CO2 storage certification

- CCS knowledge management and training.

Safety and risk management are essential across the CCS value chain. DNV de-risks CCS adoption. Drawing on industry-leading technical and project experience, regulatory and operational expertise, we offer impartial information, insights and certifications that can maximize both beneficial commercial and HSE outcomes for companies and governing authorities.

We perform full-scale and lab testing of any integrity, corrosion and safety issue at our Spadeadam, Groningen, Columbus, Ohio and Singapore test sites.