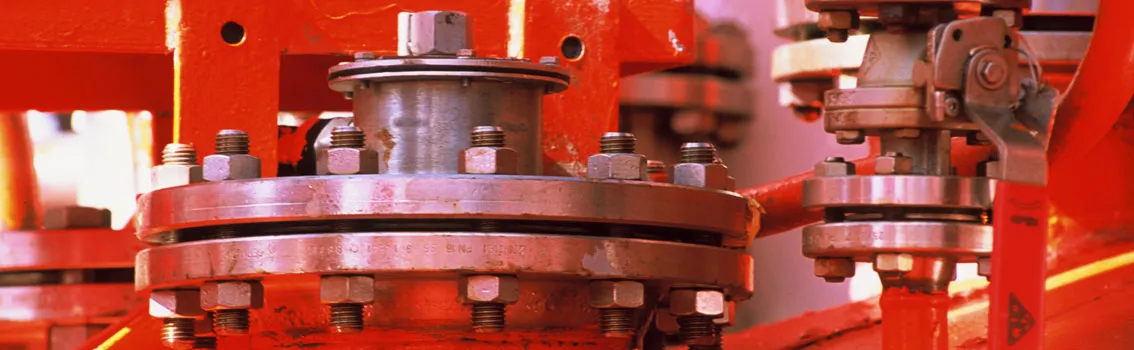

Gas valve and turbine failure

Our lab offers expert advice throughout the asset lifecycle, including support on materials and failure analysis – including gas valve failure, gas turbine failure, gas regulator failure and gas pipeline failure investigations.

Materials and failure analysis

The performance and integrity of assets – including gas valves, regulators and turbines – are influenced by an array of factors that are in turn affected by the requirements and actions of owners, operators, and regulators.

DNV has been active in materials and failure analysis for more than four decades, helping our customers to safeguard life, property and the environment, across the entire gas value chain.

With more than 50 technical specialists, we use cutting-edge imaging technology, laboratory facilities, and bespoke methodologies to provide the oil and gas industry with independent advice, and the confidence to continue safe operation and avoid future failure.

Performance and integrity can be affected throughout the asset lifecycle by materials selection and design life, environmental conditions, changes in the composition of contained fluids, and maintenance and testing procedures.

From point of production to point of use, our services encompass all assets, from subsea transmission to local distribution, and all materials used in gas pipelines, valves and turbines, from metallics and polymers to modern composites.

DNV has extensive experience in a wide range of failure investigations of gas industry components including gas turbine failure, gas valve failure, gas regulator failure and gas pipeline failure.

Our services include failure investigation and more:

- Forensic investigations into gas turbine failure, gas valve failure, gas regulator and gas pipeline failure

- Materials qualification testing, including independent corrosion, inhibitor (hydrate & corrosion) and coatings testing

- Failure analysis, including investigations of metallic and non-metallic materials failures from well to burner tip

- Forensic chemistry, including material degradation, contamination, system blockage and chemical resistance

- Welding, including weldability testing, technique development and repair strategies

- Non-destructive testing (NDT) including standard testing and evaluation of novel techniques

- Ring tension testing; yield, ultimate, fatigue and incorporating the effects of damage including corrosion, dents and cracks.

DNV assists large gas network operators to develop management protocols for NORM. Our experience in environmental testing includes radioactivity screening for NORM contamination caused by dusts and sludges produced in the oil and gas industry through pipeline or filter cleaning. Following the results of the screening, DNV can advise on the appropriate management, storage and disposal of NORM.

Some case studies follow;

- Gas turbine failure

Examples of gas turbine failure investigations include disk and blade failures in both directionally solidified and conventional cast blades. The influence of in service-corrosion, fuel quality, operational practice and maintenance intervals were examined. - Gas regulator failure

Examples of regulator failure investigations include service induced degradation of polymeric and metallic components from individual residential regulator to network gas system regulators. - Gas valve failure

Examples of gas valve failure investigations include component failures in cast valves, bolting issues, materials selection, corrosion of bolt fasteners such to adverse environmental and other operational factors. - Gas pipeline failure

Examples of gas pipeline failure investigations include metallic and polymeric pipes. Failure mechanisms such as environmental cracking - near stress corrosion cracking, graphization and fissuring of cast iron have been analysed. Other factors such as water ingress, third party inference and procedural issues have formed part of the forensic investigation.