Condition Based Maintenance (CBM)

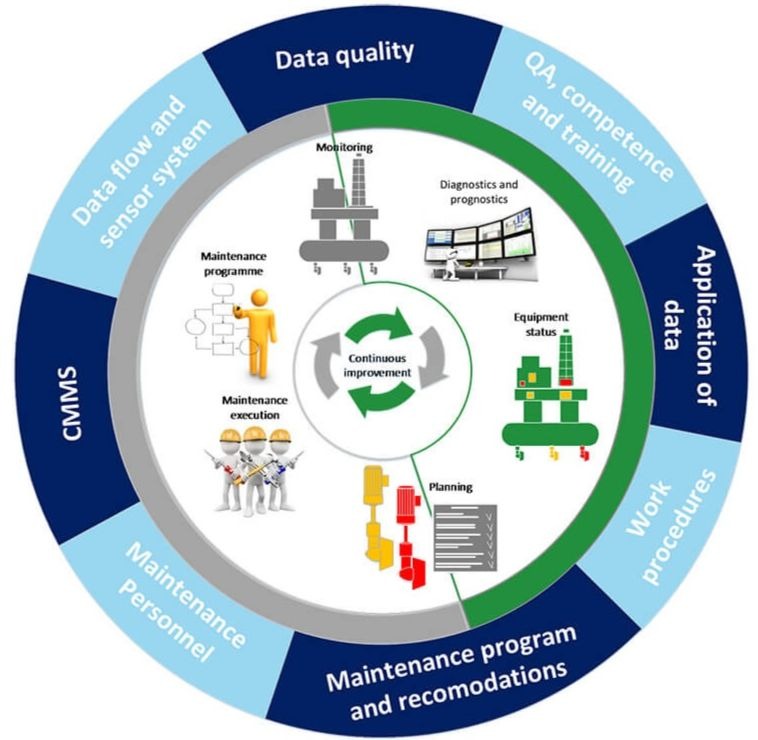

Condition Based Maintenance (CBM) survey arrangement is a survey arrangement based on a predictive maintenance approach that spot upcoming equipment failure so maintenance can be proactively scheduled when it is needed – and not before.

Performing maintenance only based on predetermined intervals or running hours will in many cases result in unnecessary maintenance and can lead to wear out or introduce failures caused by human error. This again results in reduced equipment reliability and increased downtime (out of service time).

A survey arrangement that combines predetermined (scheduled) maintenance with a predictive maintenance approach together with an approved service supplier.

Read more in our rules "DNVGL-RU-OU-0300" available here.

Figure 1: Survey arrangement CBM: Illustration of typical model

The main benefits you will get with Condition Based Maintenance:

Optimised maintenance function that only perform maintenance after a decrease in the condition of the equipment has been observed. A proactive maintenance approach provides better planning and control that avoids failures before they happen.