Smart Cable Guard technology

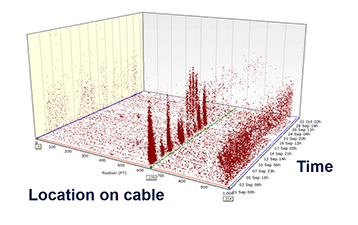

Smart Cable Guard is a proven digital solution for real-time monitoring of distribution cables. Unlike offline solutions which provide a sporadic snapshot of a cable’s condition, Smart Cable Guard offers round-the-clock monitoring for total visibility. It detects cable faults, for example caused by excavation works, in minutes. Moreover, it can identify weak spots in the cable, often many weeks or months before they develop into actual faults.

Rapid alerts via an online platform

Smart Cable Guard monitors cables via a sensor unit at each end. You can review the health status of all your monitored cables at any time via our online platform. If a fault or weak spot is detected, you will receive an alert within 5 minutes – indicating the nature, location and urgency of the issue. Additionally our expert support provides you with tailored recommendations and timelines for maintaining or replacing the affected cable.