Laboratories and test sites

We have the expertise and technologies needed to investigate and address our customers' most challenging technical needs.

Contact us

A global network of experts and facilities

DNV operates some of the most important and progressive laboratories and test sites in the industry.

Spadeadam Research and Testing, UK

Spadeadam is a world-leading research and testing site

Bishop Auckland Research and Testing, UK

One of the world's largest high-pressure natural gas flow facilities

Technology Centre Groningen, the Netherlands

Allows equipment manufacturers and oil and gas companies to test, validate and calibrate multiphase technologies

Technology Centre Tuas, Singapore

One of the most advanced materials and structural laboratories in the APAC region, serving natural gas, offshore wind, CCS, hydrogen, and other energy industry sectors

Technology Centre Bergen, Norway

Along with key services in material technology support, these laboratories have a prominent role in developing new practices and standards

Technology Centre Oslo, Norway

The on-site availability of specialist staff at DNV's Høvik headquarters enables easy integration of testing into multidisciplinary projects

Loughborough Materials and failure analysis laboratories, UK

From point of production to point of use, our services encompass all assets, from subsea transmission to local distribution, and all materials, from metallics and polymers to modern composites

Columbus Ohio materials and failure analyisis laboratory, US

One of North America’s leading materials and corrosion testing laboratories

Related articles

Cross-learning between oil and gas and floating offshore wind: Optimizing mooring design to cut cost and weight

There are many areas where technology developed for the oil and gas industry can support developments in floating offshore wind.

Custom-designed testing program supports optimization of installation weather windows for offshore wind farms

DNV testing helps quantify the effect of wave induced displacements on the performance of jacket-pile grouted connections during the installation

Testing enables life extension of mooring lines

Our laboratories are assisting operators to use securely moored oil and gas assets well beyond original design life.

Choosing the best materials to avoid environmentally assisted cracking

Expert advice before the design stage draws on testing and modelling to help specify the right materials for oil and gas equipment.

Three ways to overcome materials challenges in sour service fields

Improving asset reliability when faced with complex materials and integrity challenges in sour service field developments.

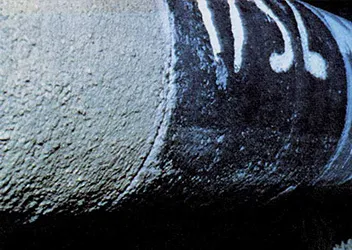

Preventing external corrosion failures

External corrosion is a threat to most equipment in every process facility and deserves closer analysis and prediction than it currently receives.

What causes materials failure in oil & gas and maritime equipment?

Systematic and thorough analysis is required to say with confidence what kind of failure is involved and what led to it

Tubes and piping are the most failure-prone components

In a study of 1,000+ cases in oil & gas and maritime, research by DNV’s laboratories also identify fatigue and corrosion to be the most common modes of component failure.

Meeting the NORM challenges in gas networks

Mixing gases from varying sources in gas networks can raise levels of natural radioactivity in dust and sludge found in pipeline systems, but complete risk-management solutions exist.

3D printed parts could benefit oil & gas, offshore and maritime supply chains

Trust is key to unlocking additive manufacturing’s potential for your business. We look at the top benefits of, and barriers to, this technology, and how DNV can help your sector to use it to become safer, more efficient and more sustainable.